The Department of Commerce has initiated the Disruptive Technology Strike Force which will partner the Bureau of Industry and Security (BIS) with the Department of Justice (DoJ) in the enforcement of the Export Administration Regulations (EAR). Export Administration Regulations (EAR) control the export of commodities determined to be dual-use. Dual-use items refer to commodities and technologies that normally are used for civilian purposes but may also be used for military purposes. The specific regulations can be found in 15 CFR §730.

Agencies now included in this enforcement will include the FBI and Homeland Security Investigations (HFI). This ongoing enforcement will include fourteen different U.S. Attorney’s Offices centered in twelve metropolitan regions. These regions include Boston, Atlanta, Chicago, Dallas, Houston, Los Angeles, Miami, New York City, San Jose, Phoenix, Portland and Washington D.C.

Actions to Protect Sensitive Technologies

These joint actions are being taken to target illicit actors attempting to acquire and export sensitive technologies from the United States to Russia, North Korea, Iran, and China. These states are using these technologies to enhance their military capabilities which, aside from posing a threat to U.S. national security can also be used to enable actions against human rights. Additionally these violations of export controls threaten economic security by threatening business that create these advanced technologies.

Pulling Out All the Stops

In enacting this enforcement U.S. enforcement agencies will use use advanced data analytics, and enhanced intelligence to coordinate actions. They will be performing more training of field agents and furthering coordination between agencies in the Intelligence Community. Furthermore there will be efforts to enhance partnerships in the private sector as well as with international partners.

The strike force will fall under the joint leadership of Assistant Attorney General Matthew G. Olsen from the National Security Division of the Justice Department and Matthew Axelrod who serves as Assistant Secretary for Export Enforcement from the Bureau of Industry and Security.

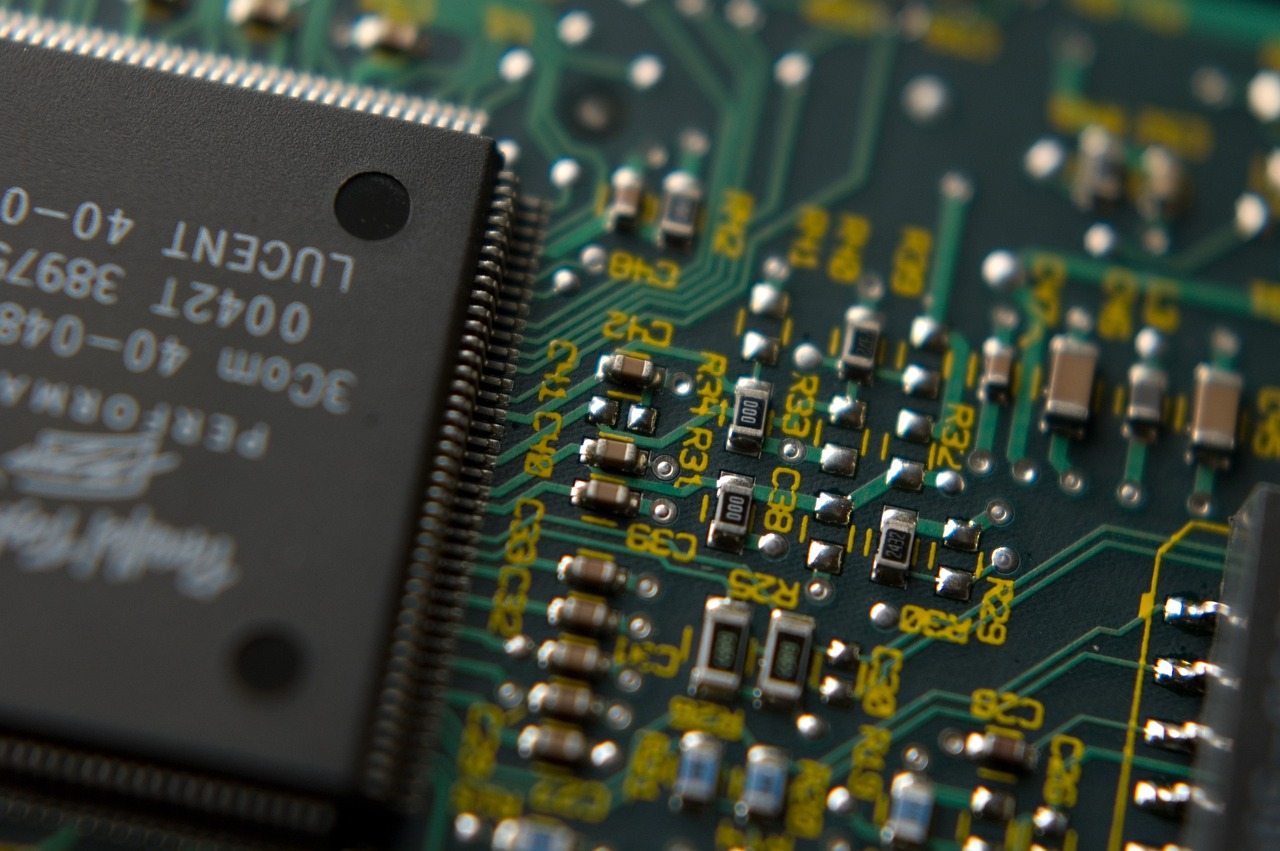

Semiconductors a Focus

The BIS has been specifically focusing on the export of semiconductors and technologies involved with the design an manufacture of semiconductors. In May of 2022, the BIS added export controls pursuant to Section 1758 on two substrates of ultra-wide bandgap semiconductors and Electrical Computer Aided Design (ECAD) tools. These actions are being taken because these types of devices have significant potential for use in military applications. Effected ECCN classifications are listed in Document Number 2022-17125.

A Call to Actions for Businesses Involved in Export

The announcement of the Disruptive Technology Strike Force shows the Department of Commerce’s commitment to continue ramping up enforcement of Export Administration Regulations. This action is the latest in a series of steps that show how serious the U.S. government is in protection of dual use items. Additionally, partners of the U.S. are coordinating efforts to enforce export control laws. Aside from enforcement, penalties both civil and criminal are increasing.

Businesses must ensure that they do not violate export regulations by enacting viable Export Compliance Management Programs (ECMP). These programs are a requirement for both the Export Administration Regulations and the International Traffic in Arms Regulations (ITAR). While businesses involved with the ITAR have been proactive in compliance, many involved with the export of dual-use goods enumerated in the EAR have been less diligent.

Export Compliance Management Programs establish clearly defined policies and procedures for all departments within an organization. They ensure that registration, item classifications, license applications, denied part screening, and security measures are taken that will prevent violation. They also ensure that training, auditing, and record keeping are maintained according to requirements.

CVG Strategy Export Compliance Management Programs

Export Compliance is an important subject for businesses engaged in sales of items that are intended for international sales or could result in international sales. Failure to comply with regulations can result in criminal prosecution including imprisonment and fines. It can also result in civil penalties and disbarment from export activities.

CVG Strategy can help you in understanding Export Administration Regulations and establishing a coherent and effective export compliance system. We can perform export control classifications, perform audits, and educate your team. Regardless of whether your business falls under EAR or ITAR, CVG Strategy has the expertise to help. Contact Us with you export regulation questions.