HASS Testing – Highly Accelerated Stress Screen

HASS Testing Improves Products Reliability

Highly Accelerated Stress Screens (HASS), previously known as “Enhanced ESS” is a a test method to find product defects introduced in the manufacturing process. These screens use the highest possible stresses to induce failure modes in items that would have normally passed less intense testing but failed after product release. As a result, warranty costs and product liabilities are reduced while increasing customer satisfaction.

What is Involved in HASS Testing?

HASS testing involves subjecting the item under test to a combination of stresses including temperature and vibration to find manufacturing defects and faulty components. The levels employed are found through Highly Accelerated Life Cycle Testing (HALT) which is often conducted in the product development phase. HALT testing uses test to fail methodologies to identify operational and failure margins. Once a product has undergone HALT, HASS can be used as part of the production process.

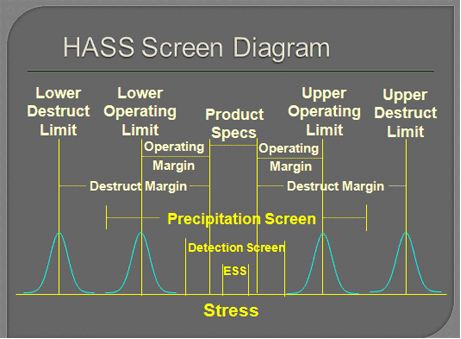

Because HASS is an accelerated form of testing it is time compressed, resulting a drastic reduction in screening equipment and manpower. This however necessitates the use of high stress levels. These screens must therefore be designed to apply acceptable levels of fatigue damage. In the diagram below the targeted levels of Stress Screening is shown.

Implementing Highly Accelerated Stress Screening

Unlike vibration test equipment found in product qualification test labs, modern HASS equipment is compact and can be operated at relatively low power costs. Although used extensively in the consumer electronics industry, HASS has gained popularity in a wide number of manufacturing sectors where quality of product is essential.

CVG Strategy Test and Evaluation Expertise

CVG Strategy can implement and integrate a Highly Accelerated Stress Screen Program once HALT has been concluded, and help to improve your production reliability dramatically. CVG Strategy has decades of experience with HALT and HASS testing. We also have experience in specific test and evaluation sectors including commercial, aerospace, automotive, defense, and EMI/EMC test and evaluation.

How Can We Help?

Take a look around our site and contact us for more information on how we can help you meet your challenges.

Latest News

Global Challenges for Cybersecurity Resilience

Global challenges for cybersecurity resilience were outlined in a recent report from the World Economic Forum. The report, Global Cybersecurity Outlook 2024, analyzes the state of