Vibration Fixture Design for Product Testing

Vibration Test Fixture Design

What is a Vibration Test Fixture?

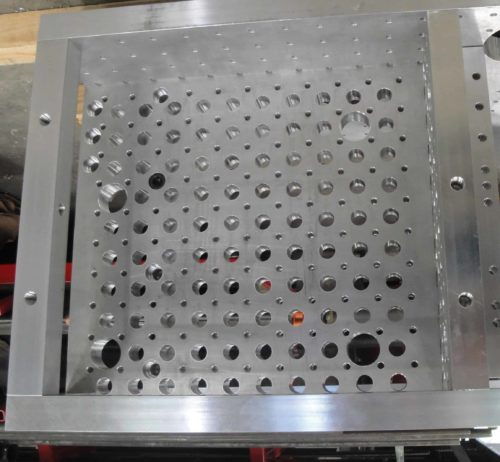

Vibration fixtures are a requirement for dynamic testing such as vibration and shock. A properly designed test fixture provides a means of mounting the equipment under test to the exciter table. As such, it is extremely important that the fixture is able to perform this function as transparently as possible, without creating resonances and nulls that can create substantial over and under test. A well designed fixture will have the required stiffness to avoid these resonances while providing low cross axis response.

Fixture Design

A vibration fixture design must give consideration to the specific geometry and mass of the product to be tested. The number of test items to be mounted must also be known. Consideration can then be given to keeping the combined fixture and test item center of gravity as low as possible.

Further consideration should also be given to the combined bandwidth of dynamic tests to be performed. Analysis can then be performed to ensure that fixture resonances do not occur.

As most dynamic testing is executed in more than one axis it can be of advantage to provide mounting holes in multiple locations.

Material selection is also a consideration. Aluminum, magnesium, and steel are materials most often employed for fixtures. Each has its own trade offs for stiffness, weight, and cost.

- Steel has excellent stiffness characteristics and is , but because of its weight, is not always the best choice. The overall weight of the fixture and item under test can often exceed the capabilities of smaller vibration test equipment. Weight is also a concern for ease of set up and break down during testing. Steel is often not the best choice for testing where higher frequencies are being used because of the potential of resonances.

- Aluminum is a good material for most fixtures. It is relatively inexpensive and is light as compared to steel. It is easily worked and can be constructed to provide the required rigidity.

- Magnesium provides the best material for tensile strength to weight ratio. It also has better dampening at high frequencies. It is however, more costly and is not as easy to machine. It is therefore usually reserved for high test performance requirements.

Access considerations should be made to make sure the test item can be quickly attached and removed from the fixture. Consideration should also be given to securing cabling that would go to power sources, simulation equipment, and monitoring equipment during testing.

Safety Concerns

In special cases where safety concerns may apply, vibration fixture design can include shielding to encapsulate the test item against possible detachment of part or rupture of pressurized vessels.

Experts in Dynamic Testing

CVG Strategy has the experts that can design vibration fixtures and build them in a timely and cost efficient matter to keep your product development on schedule. CVG Strategy’s vibration fixture design services can help you get the best results from your vibration, shock, HALT, and HASS testing.

How Can We Help?

Take a look around our site and contact us for more information on how we can help you meet your challenges.

Latest News

Global Challenges for Cybersecurity Resilience

Global challenges for cybersecurity resilience were outlined in a recent report from the World Economic Forum. The report, Global Cybersecurity Outlook 2024, analyzes the state of