Counterfeit Parts and Quality Management Systems (QMS)

AS9100 and associated standards provide a Quality Management System (QMS) approach to the problem of counterfeit parts for the aviation, space, and defense industries. These counterfeit electronics parts avoidance standards were created in response to requirements of the aerospace supply chain where counterfeit parts pose significant performance, reliability, and safety risks.

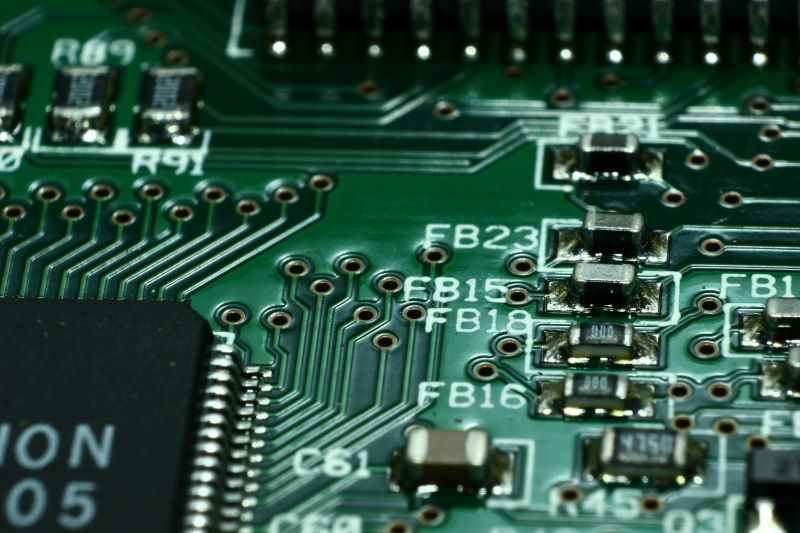

Counterfeit Parts Pose a Threat to All Industries

The best product design is only as good as its implementation. Counterfeit parts can cause failures of mission critical products causing injury and even death. While much has been accomplished by distributors of components to control the problem, the danger is still very present and costs industries billions of dollars each year.

The U.S. Department of Defense (DoD) also faces this critical issue. A Senate Armed Services Committee (SASC) report in 2012 described 1,800 instances of suspected counterfeit parts between 2009 and 2011. This report resulted in the passage of the National Defense Authorization Act (NDAA) to address DOD supply chain integrity.

New Technologies Provide Solutions

New technologies are enhancing the detection and avoidance of suspect parts. Blockchain for example is being employed to provide proof of origin for materials and components throughout the supply chain life cycle.

This highly secure encryption is utilized in smart tags. The encoded information can provide a higher degree of confidence in an item’s authenticity. Tagging mechanisms include RFID and 2D matrix codes.

Applicable Quality Management Industry Standards

AS9100D Quality Management Systems – Requirements for Aviation, Space, and Defense Organizations

AS9100D is a Quality Management System (QMS) based on the structure and content of ISO 9001:2015 with the addition of requirements specific to the aerospace, and defense industries. It also includes provisions for customer and regulatory requirements. The standard is applicable to businesses of all sizes who need to consistently provide products and services to specified requirements. Additionally, it provides processes for systematic improvement of the management system and its ability to ensure customer satisfaction.

AS9100 requirements include preventing the incursion of fraudulent counterfeit electronic parts into manufacturing cycles. It requires that specific actions be undertaken. These actions include training, establishment of a parts monitoring program, use of authorized and approved sources, traceability requirements, verification methodologies, monitoring of counterfeit part reports, and reporting and quarantining of detected or suspected counterfeits.

AS5553 – Counterfeit Electronics Parts; Avoidance, Detection, Mitigation and Disposition

AS5553 – Counterfeit Electronics Parts; Avoidance, Detection, Mitigation and Disposition was created in 2009. The newest revision, SAE AS5553D, was released in April 2022. It provides methods, requirements, and practices for parts management, supplier management, procurement, inspection, test/evaluation, and response strategies for designers and manufacturers of electromechanical parts (EEE).

These requirements are intended to be integrated throughout the supply chain. The standard calls for risk-based assessments to establish priorities for mitigation of counterfeit EEE parts. These assessments should consider vulnerabilities to crucial components, levels of desired performance, and necessary reliability of the product.

AS6081 Counterfeit Electrical, Electronic, and Electromechanical (EEE) Parts: Avoidance, Detection, Mitigation, and Disposition – Independent Distribution

This standard establishes practices for distributors and brokers of EEE parts. It requires that suppliers establish and implement quality and supply chain management systems to detect, reduce, and remove counterfeit parts. It includes methodologies for inspecting electronic components such as X-ray, XRF, and visual inspection.

Counterfeit Part QMS Solutions for Commercial OEMs

For OEMs outside of the purview of these standards there is an answer. Because ISO 9001:2015 provides flexibility in implementation for the specific requirements of a company, it allows for creation of stricter traceability requirements in the procurement process. This means a variety of standards can be implemented to the unique requirements of any OEM.

In conclusion the risk of counterfeit parts poses a threat to manufacturers in all sectors. A well-designed Quality Management System can identify such risks and mitigate counterfeit components from your products.

CVG Strategy Experts

Our Exemplar Global Lead Auditor Consultants can help you with integrating multiple management systems. CVG Strategy has prepared, trained and implemented management systems for manufacturing companies in many business sectors.

Our quality strategy allows clients new to Quality Management Systems to rapidly implement a tailored system, because everything we do as consultants is processed based. Our Quality Experts have experience with ISO9001:2015, AS9100D, ISO 13485:2016, ISO 27001:2013 and Association of American Railroads (AAR) M-1003 and can readily deliver compliant procedures and work instructions.

CVG Strategy is a consultancy offering coaching, mentoring, training and program development focused on areas including Business Process Improvement, Export Compliance, Cyber Security and Product Test and Evaluation.