Fungus MIL-STD-810 Method 508 evaluation is employed to assess a product’s susceptibility to support fungal growth. This test method is an important part of a testing program because fungus is present in a large number of environments and has numerous detrimental effects.

Effects of Fungus

Direct and indirect attacks can occur to products of natural origin as well as synthetic materials such as polyvinylchlorides, polyurethanes, polyethers, paints, and varnishes. Additionally, fungus can cause damage to electrical systems and optical systems.

Health effects from ingestion or inhalation of mycotoxins from certain species of Aspergillus mold, a fungus, can lead to skin rash, inflammation of mucus membranes, liver damage, and cancers.

Considerations

Although the standard contains an Annex to identify the basic resistance of materials to fungal growth test by analysis is not recommended. This is because of the combination of materials and their ability to support fungal growth are beyond the scope of such an analysis.

Fungus testing should not normally be conducted on the same item as used for Salt Fog/Corrosive Environments, Sand and Dust, Humidity, or Acidic Atmosphere. If these methods are performed before the Fungus method, residues left on the test item may hinder or accelerate fungal growth.

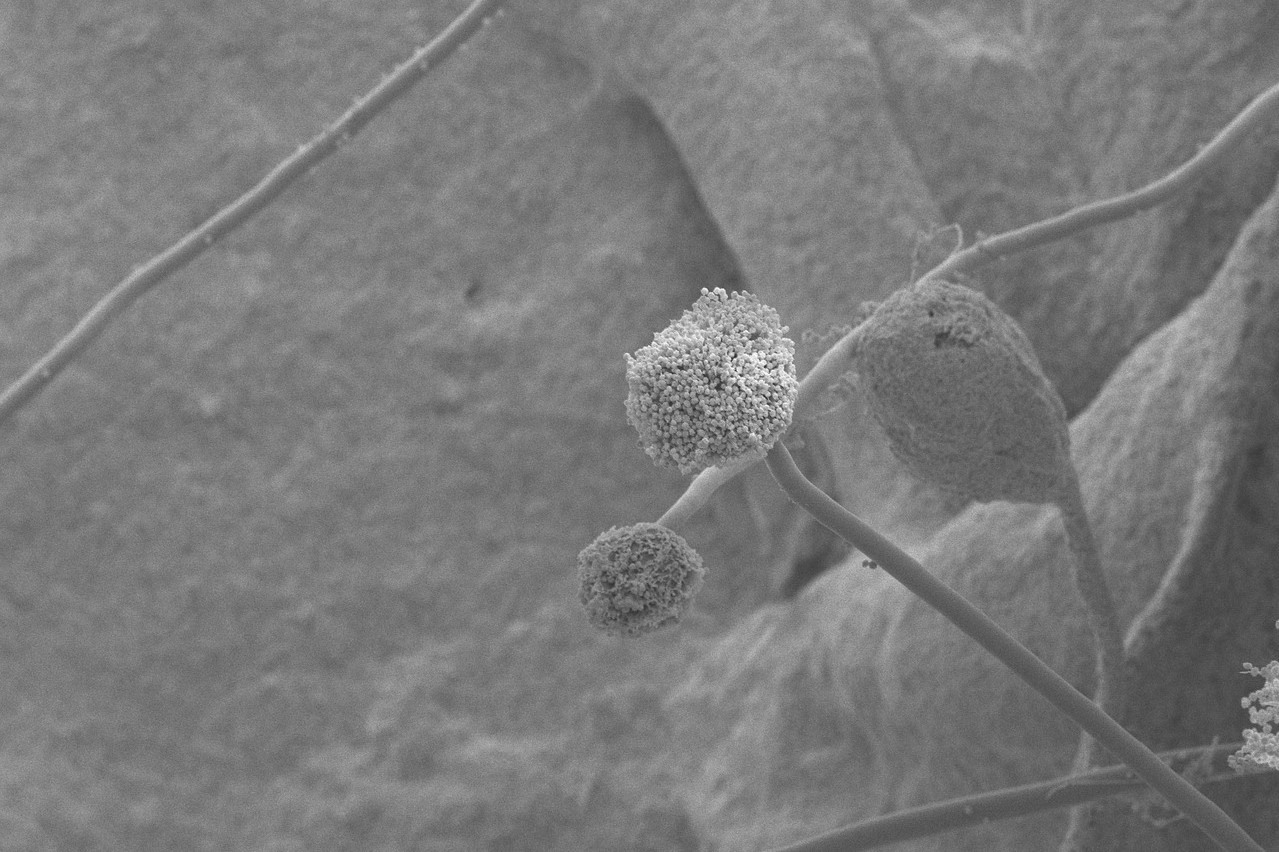

Fungus Species

A number of species are used in this method. These include Asperfillus flavus, Tricoderma virens, Talaromyces pinophilus, Chaetomium globosum, and Aspergillus brasilensis. These species are representative of destructive fungi found around the world. These species have also been selected as they are rated at Biosafety Level 1 and therefore present minimal threat to human health.

Because of the threat to human health and the fact that the procedure calls for highly-specialized techniques, it is essential that only technically qualified individuals perform these activities.

Facility Requirements

Test chambers are to be used that prevent condensation from dripping on the test item. The chamber should be monitored with sensors to allow for control of temperature and humidity. Minimal airflow is used for this method, generally under 0.5 meters/second. The chamber should be decontaminated in accordance to the guidance of Annex A in the standard.

Preparation of Test Item

It is preferable to use a new test item for this method. Before being introduced into the chamber, the unit should be cleaned, not sterilized, using a damp cloth. This cleaning should be conducted at least 72 hours before placing the item in the chamber. If cleaners other than water are used it should be noted in the test report.

A mixed sport suspension is then created and incubated. It is then verified for its ability to create fungus growth. Control strips are created from unbleached, plain weave cotton and sterilized. These are placed in the chamber to verify the spore solution is capable of producing fungus in the chamber.

The test item and cotton strips are then inoculated and left in the chamber. The chamber is kept at 86 ± 3.6 °F (30 ± 2 °C) and a relative humidity between 90 percent and 100 percent for the test duration of 28 days.

Fungus Procedure

On day 7 the cotton control strips are inspected to verify at least 90 percent coverage from mold growth and again at 14 days. If there is no increase in mold growth after 14 days the test must be restarted.

Once the 28-day duration has passed with successful results, the test item is inspected for fungus growth. It should be noted that operational or use of the test item is only to be used if essential to requirements. The results of the inspection are then recorded for the final report.

Decontamination

A complete procedure for the decontamination of equipment is described in Annex A of Method 508. Again, this activity, as with others described above, are to be performed by suitably trained personnel (e.g., microbiologists). This should be performed in a suitable facility with appropriate personal protective equipment.

Detailed Environmental Test Plans

CVG Strategy offers EZ-Test Plan Templates for MIL-STD environmental (climatic/dynamic) and EMI/EMC testing documentation. Our DETPs are written as specified in MIL-STD-810 Task 405. They are available for specific applications such as Ground Mobile, Ground Stationary, and Shipboard Controlled, Shipboard Uncontrolled, and Aircraft Military.

These DETPs include appropriate methods, (such as Fungus MIL-STD-810 Method 508) addendums for product specific information, test labels for photo identification and data sheets for collection of required data. Profile (LCEP).

Our Electromagnetic Interference Test Plans are written as specified in MIL-STD-461. They contain the test methodology, addendums for product specific information, test labels for photo identification and data sheets. These plans are available for procedures listed in MIL-STD-461 and are also available for MIL-STD-1275, MIL-STD-704, and MIL-STD-1399-300.

Custom Test Plans are also available for applications not covered in the EZ-Test Plan offerings. These plans can be written for any number of applications and their relevant standards.

Put CVG Strategy’s Experience to Work for You

Companies of all sizes, from start up to established product developers, face challenges in product test and evaluation. This can particularly be the case when a product is developed for a new market sector or expanding sales internationally.

Properly tested products prevent costly product recalls, product redesign, and product liability. They maintain customer satisfaction and keep your company’s reputation in good standing. Contact CVG Strategy to see how our services can assist your engineering team with Fungus MIL-STD-810 Method 508 or any other test and evaluation concern.

MIL-STD-810 Training Classes

CVG Strategy MIL-STD-810 classes will provide you with the ability to develop and conduct an environmental test program. Our two-day course not only provides you with valuable information about climatic and dynamic test methods but also includes training in the methodology to correctly apply test tailoring relevant to the test item’s expected life cycle.

This course is available online or onsite. Ample time is available for questions and comments so that participants are encouraged to keep engaged. Check here for our online Training Registration Schedule.