FCC Streamlines Approval Process

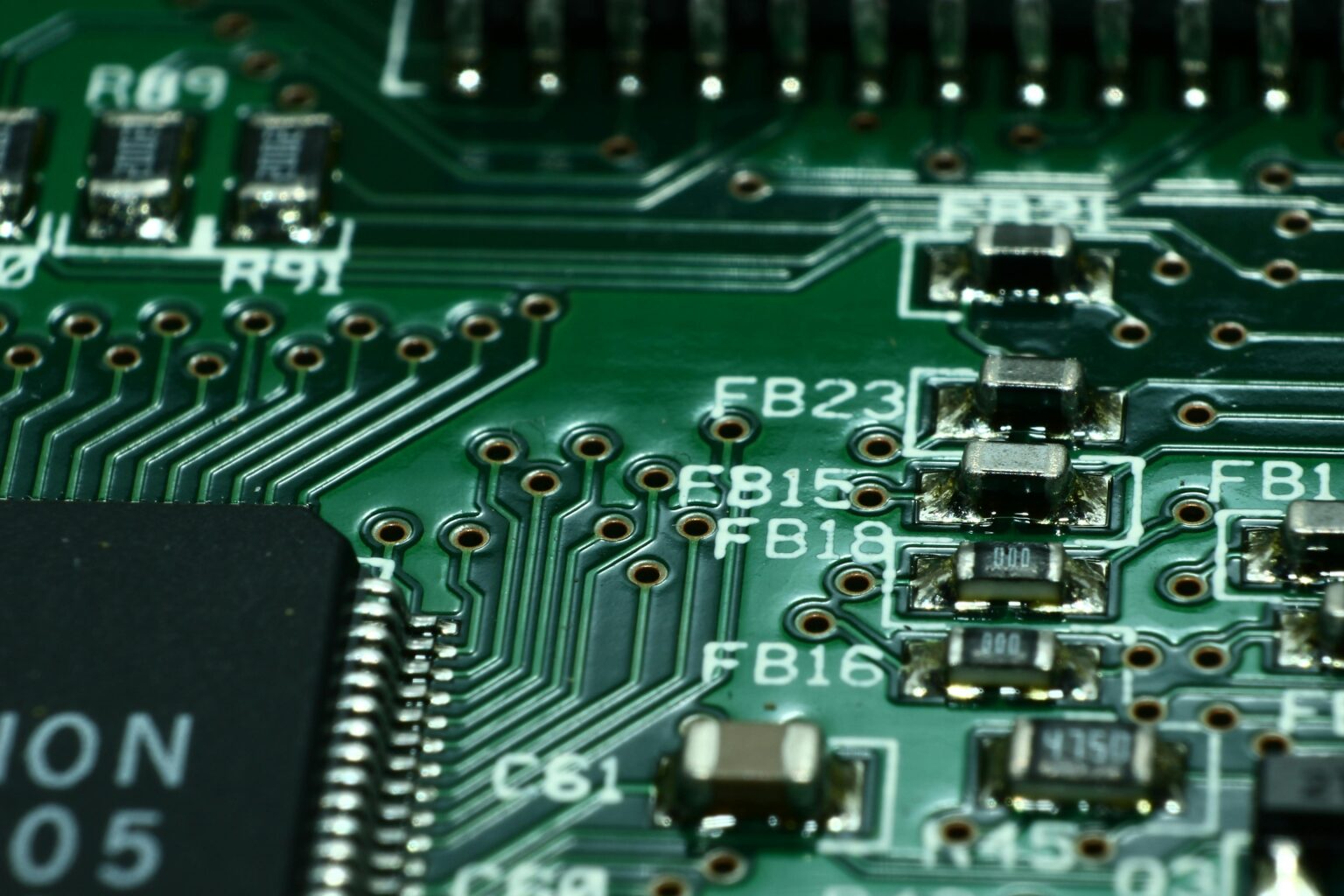

The FCC approval process has been streamlined for unintentional radiators. Most electronic devices create radio frequency (RF) energy. This energy can interfere with devices. Intentional radiators are devices which communicate by way of radio frequencies (Bluetooth, Wi-Fi, radio). Unintentional radiators create RF energy from their power supplies and digital components. These devices are therefore less likely to interfere with the communications of other devices.

Because the previous requirements were confusing and time consuming the FCC’s streamlining of the approval process is a welcome relief to manufacturers of electronic products.

Supplier’s Declaration of Conformity (SDoC)

Previously the FCC required Verification and a Declaration of Conformity (DoC). The new FCC approval process no longer requires Verification for unintentional radiators. It now relies solely on the Supplier’s Declaration of Conformity (SDoC). The SDoC is comprised of the following steps:

- Electromagnetic Compatibility (EMC) testing must be performed that conforms to FCC compliance standards.

- Preparation of a compliance information statement that includes product information, a list of a standards to which the product is compliant and the identification of a responsible party in the United States or its territories.

- The end user of the product must receive FCC approval compliance information in a paper or electronic user manual.

- The device should be labeled. The label should uniquely identify a product name, identification number and/or description.

- A FCC label can be affixed, though not required. An electronic label can be used for products with display capabilities.

CVG Strategy

Our experts at CVG Strategy have extensive experience in the FCC approval process. We have the experience in EMI/EMC to guide you in requirements for both commercial and military products. CVG Strategy can provide pretest analysis, thereby reducing EMI emission test failures and their resultant delays. We also have expertise in Environmental testing and evaluation in a number of industries and products. CVG Strategy specializes in Independent Developmental Testing and Evaluation including: Development of Life Cycle Environmental Profiles, Test Plans, Test Witnessing and Troubleshooting.

CVG Strategy is a consultancy offering coaching, mentoring, training and program development focused on areas including Business Process Improvement, ITAR and Export Compliance, Cyber Security and Quality Management Systems.