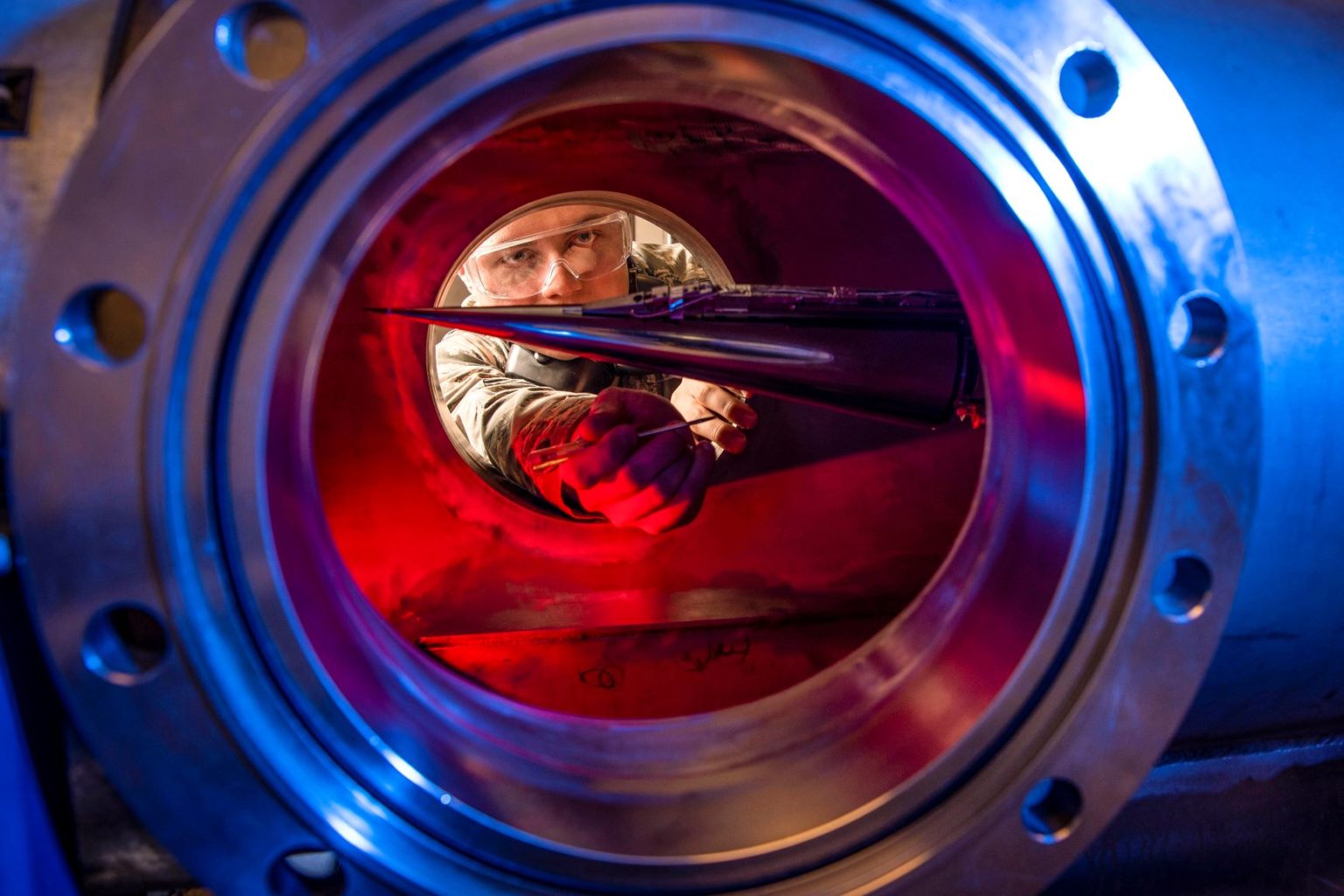

Components for hypersonic applications are required for an increasing number of Department of Defense (DoD) projects. These components and assemblies must be able to function under very demanding circumstances. Typical stresses include altitudes exceeding 100,000 feet, rapid temperature changes, vibration, pyroshock, and acceleration. This provides unique challenges to designers and those involved in test and evaluation.

Design Challenges for Components for Hypersonic Applications

Current defense designs can involve flight speeds of anywhere from Mach 5 (3,800 mph) to Mach 10 (7,600 mph). Future designs may reach speeds near Mach 30 (23,000 mph). This produces high levels of vibration, shock, and heat.

These stresses require that each device for a printed circuit board must be carefully selected. Furthermore, care must be taken in the design of circuit boards to avoid failures at connection points. Care must also be taken to prevent resonances that can destroy components or cause intermittent failures due to to piezoelectric effects.

These requirements for rugged designs are driving development of new cooling, adhesive, and dampening solutions. The outcomes will likely result in revolutionary technologies.

Hypersonic Test and Evaluation Requirements

Often testing for these designs must be performed for both qualification and acceptance of system components. This requires vast resources of test equipment and test facility time. Additionally, because parameters are extreme, equipment capable of performing a test can be difficult to find.

To complicate matters, test values can often fall outside the capabilities of test equipment at both ends of the spectrum. This can be the case with pyroshock where a value is too large for an electodynamic shaker systems but beyond the lower limits of a resonant beam device. Pyroshock is a critical test because it involves dynamic forces with a frequency range extending to 10,000 Hz.

CVG Strategy Product Testing Services

CVG Strategy provides program management for defense and commercial test and evaluation. We can work with multiple test facilities to coordinate testing on high end test equipment required for analysis where reliability is essential. Our experts can ensure that testing is performed as required and that essential data is recorded. Contact us for answers and solutions to your test and evaluation challenges.