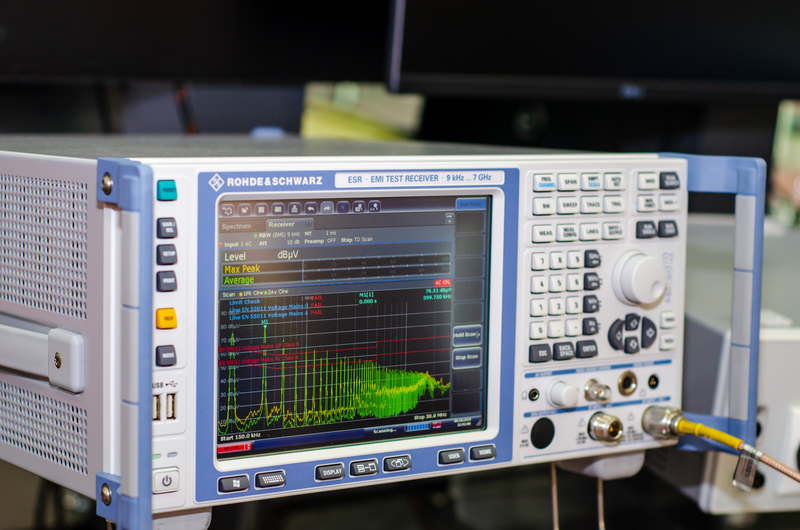

Preparing for EMI Testing can save time and money. Most EMI tests do not provide the news we want to hear on the first trip, therefore preparing to go the lab then is a task that should be thought out.

Emissions and immunity testing is an important part of your product development. Successful testing can provide compliance to relevant international standards and allow you to get your product to market. It can also ensure your product is not susceptible to interference that can cause damage, injury, and product recalls.

Pre Compliance Testing

There are many EMC pre-compliance tools available to product developers today. These can provide screening to prevent trips to a lab when a product would clearly fail. They can also aid in troubleshooting to evaluate required design modifications. While these tools can definitely provide an edge for emissions testing they are not as useful for immunity, susceptibility, and power compatibility testing.

Pre test Product Evaluation and Susceptibility Analysis

EMI/EMC expertise can help solve difficult EMI/EMC issues. Our EMI/EMC experts have decades of experience and help provide analysis and design modifications to address design deficiencies. We can also provide a susceptibility analysis for safety critical devices. This type of analysis is now a requirement for medical devices that must pass coexistence testing.

Equipment to be Tested

We can start by taking a close look at what the product item we are sending. Is it truly representative of the finished product? Will it be running with representative firmware and software? Are the cables representative of the finished product? All of these factors will greatly effect the veracity and data provided from the test.

Often early manufactured samples of a product will have coatings where they shouldn’t be. Check your test item for unwanted paint or powder coat that could interfere with grounding of enclosures and connectors. Removing paint at the lab is time consuming and time goes by very quickly at the lab.

Have EMI/EMC Test Plans

Another way to prepare for EMI testing is to know what tests are required and understand which sequence of tests are to be run. Write EMI test plans to communicate product specific information among the design team, the test lab, and the customer. These information can include pass/fail criteria for modes of operation to be tested in immunity testing.

In the defense industry, a test plan can be a contract requirement. Aside from documentation of desired procedures the writing of the procedure will reinforce and deepen the Test Witnesses understanding of test details.

The Kitchen Sink

When preparing for EMI testing make sure you have appropriate support hardware to exercise the equipment under test so that operational modes are representative of the product in its intended usage.

Bring extras of everything. If you have had enough forethought to provide extra component places on printed circuit boards near I/O connectors for ferrites and capacitors bring plenty of different values to play with if required. Bringing your own soldering equipment can be useful as well. Always bring multiple samples of the equipment to be tested and extra cables.

Most importantly, bring an appropriate mind set to your EMI test. Everybody wants to bring home a win, but bringing back important data from a test failure is invaluable. Remain flexible and be prepared to change course so that you can best isolate and analyze the causes of failure. This will involve cooperation with lab personnel so developing and maintaining a good working relationship with these people is very important.

CVG Strategy Experts

Our experts at CVG Strategy have extensive experience in Environmental/Dynamic and EMI/EMC testing for a number of industries and products, both military and commercial. CVG Strategy specializes in Independent Developmental Testing and Evaluation including development of Test Plans, Test Procedures, Test Witnessing and Troubleshooting.

CVG Strategy is a consultancy offering coaching, mentoring, training and program development focused on areas including Business Process Improvement, ITAR and Export Compliance, Cyber Security and Quality Management Systems. For any additional questions, please contact us now!