What Test Witnesses Need to Know About Accelerometers and Laboratory Testing

Shock and Vibration analysis utilizing accelerometers and laboratory testing is a requirement for many commercial and defense standards. Because accelerometers provide the feedback to the excitation system, proper selection and placement is essential. To achieve optimal testing validity the test witness and test manager should have some knowledge about accelerometers and how they are used so as to provide valuable information to the laboratory personnel setting up the test.

Pre-test Preparation for Dynamic Testing

Having a fixture that is designed for your test item is optimal. Having the same fixture to mount your test item on ensures that a test is repeatable. This fixture should be characterized prior to testing so that no resonances or nulls to the shock or vibration profile are being introduced to the Unit Under Test (UUT). Fasteners used should be characteristic of those to be used in the product’s intended installation and should be tightened to the specified torque. Furthermore the UUT should be mounted on the fixture identically for all tests.

Know the Parameters of the Tests

Because of the wide range of possibilities, it is important that the test witness be aware of the characteristics of the profiles to be used in a dynamic tests. These characteristics include the frequency range and the amplitudes. It is a good idea to review this information from the test plan with the laboratory test engineer to ensure proper accelerometer selection. Selection of an appropriate accelerometer is essential because of the wide variety of usable frequency range and amplitude scale.

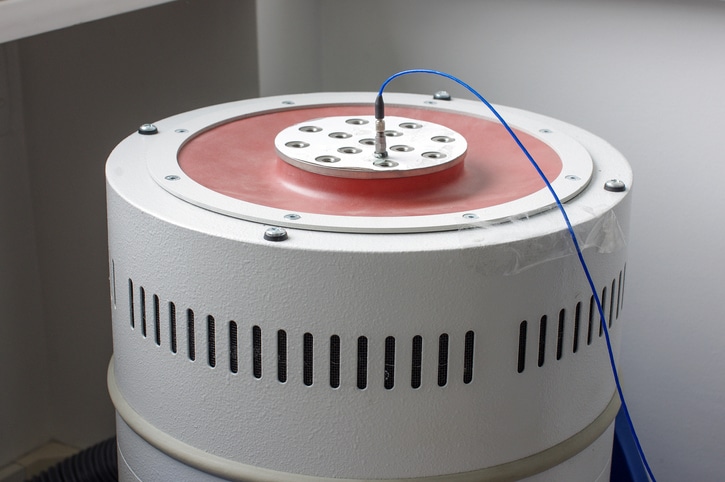

Mounting of the Accelerometers

The method of mounting an accelerometer can greatly effect its frequency response. Methods for mounting include stud mounting, adhesive, and adhesive mounting pad.

When practical stud mounting provides the maximal frequency response. Often a coupling fluid such as grease or beeswax is used to enhance frequency response to compensate for surface flatness or roughness. If these are used the specific medium used should be documented so that the test parameters can be replicated.

There are small differences between adhesives in their frequency responses. Often Loctite 454 is used. Generally these work well. For testing where large forces are at play however, such as hammer shock tests used in shipboard shock and ballistic shock, adhesives are not advised. These adhesives can fail during the test resulting in necessary retest and possible over test of the UUT.

Once the location of the accelerometer(s) have been established and validated the locations and means of mounting should be documented. Documentation, preferably by photo, should also show the means of securing the accelerometer wiring because base strains caused by wiring can effect the response of the sensor.

Other Considerations

The vast majority of test laboratory engineers are well informed about the dynamic testing they perform on a regular basis. They however, need to know about any specific information particular to the UUT. If dynamic testing is to be conducted with the UUT in an operational state, areas that reach high temperatures should be noted. If these areas are used for mounting the test engineer may have to utilize thermal compensation. Additionally if the UUT generates extreme magnetic fields shielding might be required.

CVG Stategy Test and Evaluation Experts

CVG Strategy has performed test and evaluation for a wide range of commercial and military applications. We have extensive experience in dynamic, climatic, and EMI/EMC. We can provide test program management, test witnessing, test program documentation, and product evaluation. Contact us to see how we can help you get the most from your test and evaluation program.