MIL STD 810H Humidity

MIL STD 810H Humidity Method 507.6 is a test method for evaluating products that are likely to be stored and/or operated in a warm, humid environment. MIL-STD-810 Environmental Engineering Considerations and Laboratory Tests is a Department of Defense (DoD) standard for military and commercial applications. It is a series of laboratory test method that replicate the effects of environments on products. These methods are meant to be tailored to the specific environmental effects expected during the life cycle of the product. This is an important consideration because there are few definable goal posts in this standard. Tailoring is required because the environmental effects likely to be encountered on equipment designed for aircraft, for example, will be quite different from those found on a vehicle.

Effects of Humidity

The effects of humidity are often overlooked when faced with more obvious environmental stressors such as temperature, shock, and vibration, but there are numerous physical and chemical effects that humidity can take place both within and on the exterior of equipment. For surface effects; oxidation, electrochemical breakdown of coatings, interaction with deposits of materials that produce corrosive films, and changes in friction coefficients. Other effects include; loss of physical strength of materials, degradation of insulative properties, changes in elasticity or plasticity, and degradation of lubricants.

Humidity Testing

Humidity is an extremely complex environmental phenomena that is intricately linked with temperature. There a limitations in what a laboratory method can reproduce and simulate. Method 507.6 is comprised of two procedures.

- Induced (Storage and Transit) and Natural Cycles

- Aggravated

For procedure I, induced cycles of temperature and humidity are used to simulate various storage and transit scenarios where equipment is packaged or stored in environmentally uncontrolled warehouses. The standard points out that multiple tests may be applicable for storage or transit based on the nature of those sequences and nature of packaging. Natural cycles are intended for the testing of equipment in its intended environmental conditions.

Procedure II exposes the test item to more extreme temperature and humidity levels than those found in nature, but for shorter durations. While this can be an advantage for early detection of design vulnerabilities, results may not accurately represent those found in nature.

Climatic Considerations

Conditions of humidity vary considerably across the globe. MIL-HDBK-310 defines three geographical categories that are used for generation of cyclic profiles.

B1 – Constant High Humidity

This profile is representative of conditions found in heavily forested areas with little solar radiation exposure. Geographical locations typical of this profile are Congo and Amazon Basins, the jungles of Central America, Southeast Asia (including the East Indies), the north and east coasts of Australia, the east coast of Madagascar, and the Caribbean Islands.

B2 – Cyclic High Humidity

B2 profile occurs in the same areas as B1 but is more representative of urban areas where solar radiation exposure is expected. Solar radiation when present in the diurnal cycle creates a wider variance in temperature and humidity.

B3 – Hot-Humid

This profile is found in areas near bodies of water with high surface temperatures, specifically the Persian Gulf and Red Sea. Testing for this extreme condition does not verify the unit under test’s ability to endure the rigors of B1 or B2.

Additional Categories

Additional categories are provided for induced environments where temperatures as high as 160 °F (66 °C) can be reached for enclosed environmental conditions where little or no cooling air is available. These induced categories are meant to replicate various transport and storage scenarios.

Test Duration

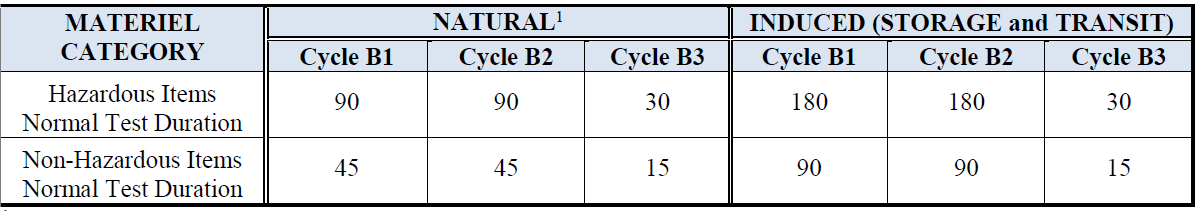

The effects of humidity require lengthy test durations to evaluate potential degradation. Often testing is not performed at adequate lengths to provide meaningful data. MIL STD 810H Humidity Method 507.6 durations are shown in the table below.

Hazardous Items

MIL-STD-810 states that hazardous test items will generally require longer tests than other items to achieve a desired confidence. The standard defines Hazardous test items as “those in which any unknown physical deterioration sustained during testing could ultimately result in damage to materiel or injury or death to personnel when the test item is used”. It calls for double the number of cycles for hazardous items.

Non-Hazardous Items

For Natural Cycles, generally intended for operational testing, Method 507.6 calls for 15 to 45 tewnty-four hour cycles of testing dependent on which geographical area the equipment may be used in.

Aggravated Cycles

For Aggravated testing per Procedure II, ten cycles are recommended in addition to a 24 hour conditioning period. Again the proviso for lengthening for hazardous items is called out but no exact measure is indicated.

The Conundrum

For humidity testing there is often more questions than answers. Today’s defense and commercial equipment is liable to be used anywhere in the world. Given that time and money are major concerns for most product developers, it is unlikely that resources are available for testing all climatic categories for transit, storage, and operational profiles. While Aggravated testing is tempting due to its shortened test length it may not provide realistic findings. Unless product specifications specify exact testing requirements difficult decisions must be made.

CVG Strategy

CVG Strategy’s test and evaluation experts have decades of experience in environmental (climatic and dynamic) testing as well as EMI/EMC. We offer a wide variety of services including: EZ-Test Plan Templates, Test Program Management, Test Program Witnessing, and Product Evaluation. We also provide a two day seminar/webinar “Understanding MIL-STD-810” to help your product development team garner the most from their test and evaluation programs. Contact Us today to see how we can help.